You may have read or heard us discuss that our iron works are powder coated. Now, we’re not talking baby diapers here people! Our version of powder coating involves a process that was patented back in 1953 by Dr. Erwin Gemmer, a German scientist.

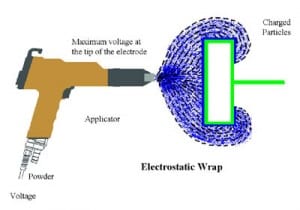

The powder coating process starts out by pre-treating the part to remove any oil, dirt, or other contaminants. Next, the actual powder is sprayed onto the metal part using an electrostatic gun.  This special guns puts a positive charge on the powder while the metal piece has a negative charge. Naturally, the two are attracted to each other! Finally, the metal piece is cured in a special oven. The heat during the curing process melts the powder and it flows smoothly over the part. When it cools, you’re left with a beautiful and durable finish.

This special guns puts a positive charge on the powder while the metal piece has a negative charge. Naturally, the two are attracted to each other! Finally, the metal piece is cured in a special oven. The heat during the curing process melts the powder and it flows smoothly over the part. When it cools, you’re left with a beautiful and durable finish.

All of the “iron” works (remember, we actually use heavy gauge steel) we sell are powder coated for strength, durability, and beauty. Check out some of the doors, gates, rails and other enclosures offered by Iron Crafters.